Exhaust gas hoses play a crucial role in various industries by safely channeling harmful gases away from engines and machinery. These hoses are vital for maintaining operational efficiency and ensuring safety in environments where exhaust gases are produced. We will explore the different types, applications, and benefits of exhaust gas hoses, as well as the materials used in their construction and future trends in the industry.

What are Exhaust Gas Hoses?

Exhaust gas hoses are specialized conduits designed to transport exhaust gases from engines or industrial processes to designated discharge points. They are engineered to withstand high temperatures and corrosive substances, ensuring the safe removal of potentially hazardous emissions.

Types of Exhaust Gas Hoses:

- Flexible Hoses: Made from materials like silicone or rubber, these hoses offer excellent flexibility and vibration absorption. They are commonly used in applications where movement and flexibility are required, such as in automotive exhaust systems

- Metal Hoses: Constructed from stainless steel or other metals, these hoses provide superior durability and heat resistance. They are ideal for high-temperature applications and environments where chemical resistance is crucial

- Composite Hoses: These hoses combine multiple materials to offer a balance of flexibility, strength, and chemical resistance. They are often used in industrial settings where a combination of properties is needed

Marine and Industrial Applications of Exhaust Hose

Automotive Industry: Exhaust gas hoses are integral to vehicle diesel engine exhaust systems, helping to reduce emissions and improve air quality. They are used in both passenger cars and commercial trucks. In modern vehicles, these hoses are designed to meet stringent emission standards, ensuring that harmful gases are effectively filtered and expelled

Industrial Use: In industrial settings, exhaust gas hoses are employed in ventilation systems to remove harmful gases from manufacturing processes, ensuring a safe working environment. Industries such as chemical manufacturing, metal processing, and power generation rely on these hoses to maintain air quality and protect workers from exposure to toxic fume in exhaust gas systems

Marine Applications: Ships and boats use wet exhaust gas hoses to manage emissions from their engines, contributing to cleaner marine operations. These marine hoses are designed to withstand the harsh marine environment, including exposure to salt water, marine fuel and extreme temperatures in marine exhaust systems

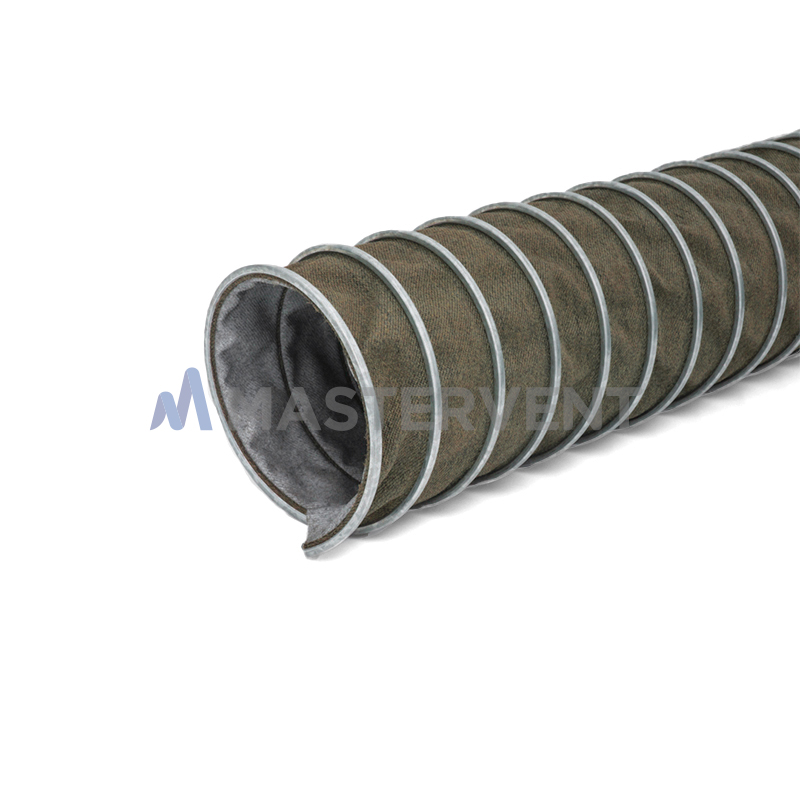

Key Features and Benefits of Clip Hoses with Steel Spiral

Durability: Clip exhaust gas hoses are designed to withstand extreme temperatures and harsh conditions, ensuring long-term performance. High-quality materials and construction techniques are used to enhance their durability, making them suitable for demanding applications

Flexibility: Many exhaust gas hoses are flexible, allowing them to absorb vibrations and accommodate movements without damage. This flexibility is particularly important in automotive and marine applications, where engines and machinery are subject to constant movement

Safety: By effectively channeling exhaust gases away from sensitive areas, these hoses help prevent exposure to harmful emissions, protecting both people and equipment. Properly designed and maintained exhaust gas hoses are essential for compliance with safety regulations and environmental standards

Materials Used for Super Exhaust Gas Hoses

Metals: Stainless steel and aluminum are commonly used for their heat resistance and durability. These metals can withstand high temperatures and corrosive environments, making them ideal for exhaust gas applications

Composites: Composite materials offer a combination of strength and flexibility, making them suitable for various applications. These materials can be engineered to provide specific properties, such as resistance to chemicals or extreme temperatures

Other Materials: Depending on the specific requirements, other materials like silicone or rubber may be used to enhance flexibility and chemical resistance. These materials are often used in flexible hoses where movement and vibration absorption are important

Clamp Installation and Maintenance

Installation Tips: Proper installation is crucial for the optimal performance of exhaust gas hoses. Ensure secure clamp connections and avoid sharp bends that could cause damage. It is important to follow manufacturer guidelines and use appropriate fittings and clamps to secure the hoses

Maintenance Practices: Regular inspections and maintenance are essential to detect wear and tear early. Replace hoses as needed to prevent leaks and ensure safety. Maintenance practices should include checking for signs of damage, such as cracks or abrasions, and ensuring that hoses are properly secured and free from obstructions

Challenges and Solutions

Common Issues: Exhaust gas hoses can suffer from wear and tear, leading to leaks or blockages. High temperatures and corrosive gases can accelerate degradation. Common issues include cracking, splitting, and loss of flexibility, which can compromise the hose’s performance

Innovative Solutions: Advances in materials science and engineering have led to the development of more durable and heat-resistant hoses, reducing the frequency of replacements and maintenance. Innovations such as reinforced composite materials and improved manufacturing techniques have enhanced the performance and longevity of exhaust gas hoses

Future Trends Description

Technological Advancements: Ongoing research is focused on developing new materials and designs that offer even greater durability and efficiency. Future exhaust gas hoses may incorporate smart technologies, such as sensors to monitor performance and detect issues in real-time

Market Trends: The demand for exhaust gas hoses is expected to grow as industries continue to prioritize environmental compliance and operational safety. Increasing regulations on emissions and a focus on sustainability are driving the development of more efficient and eco-friendly exhaust gas solutions

Exhaust gas hoses are indispensable components in various industries, ensuring the safe and efficient removal of harmful emissions. As technology advances, these hoses will continue to evolve, offering improved performance and contributing to a cleaner, safer environment. Proper selection, installation, and maintenance of exhaust gas hoses are essential for maximizing their benefits and ensuring long-term reliability.

We have a big range of exhaust hose products available in different size and length (linear meter) also with a textile wall, lightweight steel helix and crush proof steel spiral. Find more information about black TPE hoses for suction and extraction of hot fumes on our website. Call us or buy online!

Vent Clip Pur

From: 211,04 € *Unit price per 1 m plus VAT plus shipping costs

Vent Clip Pur

From: 211,04 € *Unit price per 1 m plus VAT plus shipping costs

Vent Clip PE

From: 205,04 € *Unit price per 1 m plus VAT plus shipping costs

Vent Clip PE

From: 205,04 € *Unit price per 1 m plus VAT plus shipping costs

Vent Clip Spark

From: 206,96 € *Unit price per 1 m plus VAT plus shipping costs

Vent Clip Spark

From: 206,96 € *Unit price per 1 m plus VAT plus shipping costs