RECOMMENDED

-

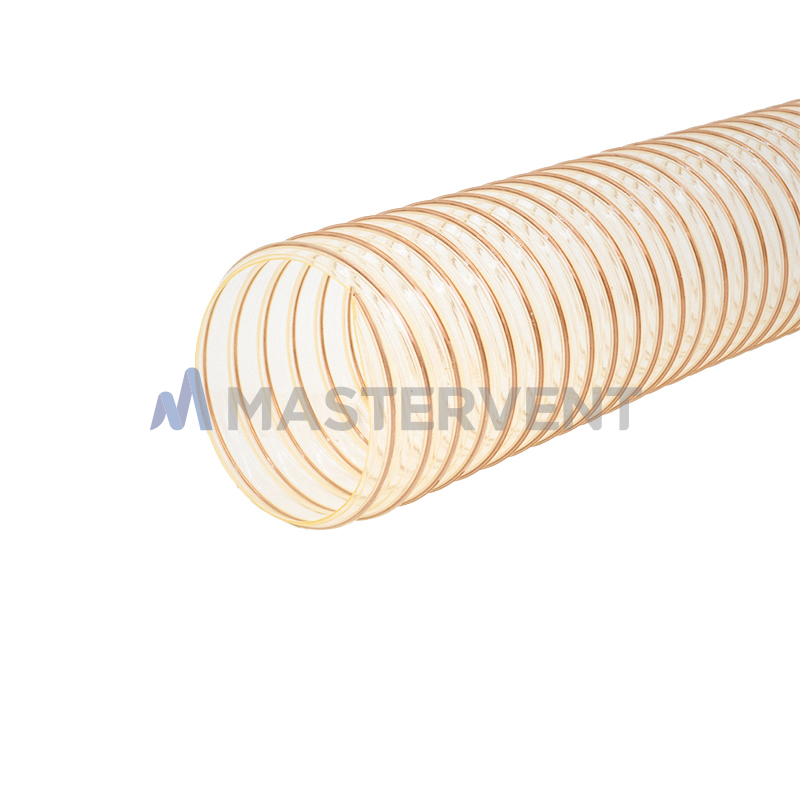

Vent Clip Pur

From: 202,88 € *Unit price per 1 m plus VAT plus shipping costs

Vent Clip Pur

From: 202,88 € *Unit price per 1 m plus VAT plus shipping costs

-

Vent Clip PE

From: 201,31 € *Unit price per 1 m plus VAT plus shipping costs

Vent Clip PE

From: 201,31 € *Unit price per 1 m plus VAT plus shipping costs

-

VENT CLIP SPARK - Gas Welding Hose

From: 207,25 € *Unit price per 1 m plus VAT plus shipping costs

VENT CLIP SPARK - Gas Welding Hose

From: 207,25 € *Unit price per 1 m plus VAT plus shipping costs