In industries where extreme temperatures are, a daily challenge, high temperature resistant hoses are indispensable. These specialized hoses are designed to withstand the harshest conditions, ensuring safety and efficiency in various applications. We will explore the types, applications, key features, selection criteria, maintenance, and future trends of high temperature resistant hoses.

Types of High Quality Temperature Resistant Hoses

Material Composition

High temperature resistant hoses are made from materials like silicone, Teflon, and stainless steel. Each material offers unique properties that make it suitable for specific applications:

- Silicone Hoses: Known for their flexibility and excellent heat resistance, silicone hoses can withstand temperatures ranging from -60°C to 200°C. They are commonly used in automotive and industrial applications where flexibility and durability are crucial

- Teflon (PTFE) Hoses: Teflon hoses offer exceptional chemical resistance and can handle temperatures up to 260°C. They are ideal for chemical processing industries where exposure to harsh chemicals and high temperatures is common

- Stainless Steel Hoses: These hoses provide superior durability and can withstand both high temperatures and high pressures. They are often used in aerospace and heavy machinery applications where reliability and strength are paramount

Design Variations

High temperature resistant hoses come in various designs, each tailored to specific needs:

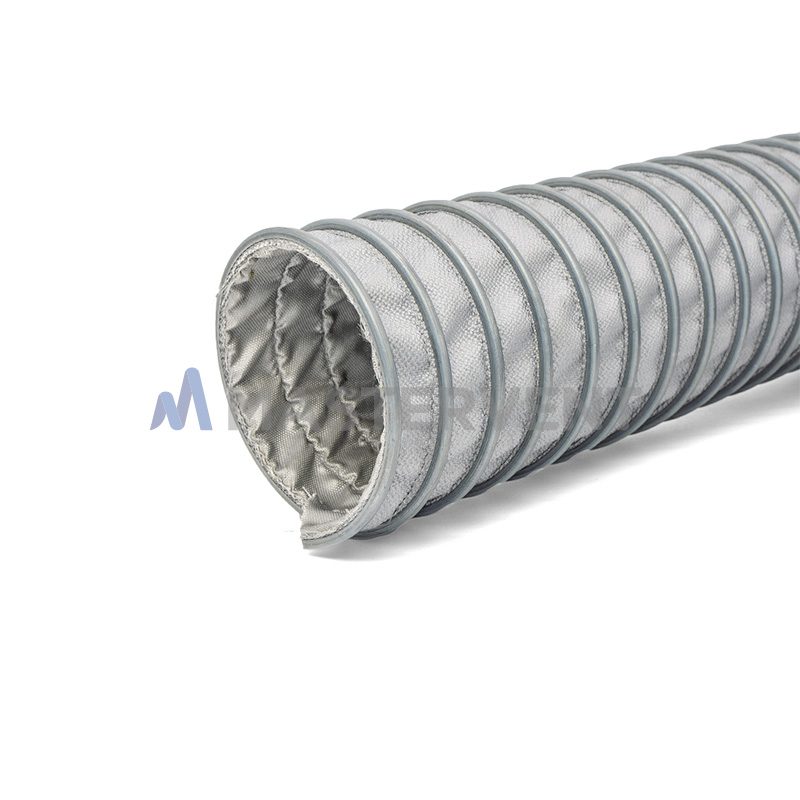

- Braided Hoses: These hoses have, a braided outer layer that enhances their tensile strength and flexibility. They are suitable for applications requiring high pressure and flexibility

- Corrugated Hoses: Featuring, a corrugated design, these hoses offer excellent flexibility and are ideal for applications requiring tight bends and movement

- Smoothbore Hoses: With, a smooth inner surface, these hoses ensure, a smooth flow of fluids, reducing the risk of blockages and improving efficiency

Applications and Industries

Industrial Use

High temperature resistant hoses are crucial in various industrial sectors:

- Chemical Processing: In chemical plants, these hoses transport corrosive and high temperature fluids safely, ensuring the integrity of the process and the safety of workers

- Automotive Industry: In the automotive sector where they have direct contact with vehicles and petroleum, high temperature resistant hoses are used in engine cooling systems, exhaust systems, and turbochargers, where they handle high temperatures and pressures

- Aerospace Industry: Aerospace applications include fuel and hydraulic systems where extreme temperatures and pressures are common. High temperature resistant hoses ensure the safe and efficient operation of these systems

Commercial Use

These hoses are also used in commercial settings:

- HVAC Systems: In heating, ventilation, and air conditioning (HVAC) systems, high temperature resistant hoses handle hot air and fluids, ensuring efficient heating and cooling

- Household Appliances: Household appliances like ovens, dryers, and dishwashers use these hoses to manage high temperatures safely, ensuring reliable performance and safety

Specialized Applications

High temperature resistant hoses are essential in specialized applications:

- Laboratories: In laboratories, these hoses transport hot fluids and gases, ensuring precise and safe handling of materials

- Food Processing: In the food processing industry, high temperature resistant hoses handle hot liquids and steam, ensuring hygiene and safety in food production

Key Features and Benefits of Hoses with Heat Resistance

Temperature Resistance: High temperature resistant hoses can withstand a wide range of temperatures, from -100°C to 170°C and over 1000°C, depending on the material. This makes them suitable for various applications, from industrial processes to household appliances

Durability and Longevity: Made from robust materials, these hoses offer long service life even under extreme conditions. They resist wear and tear, reducing the need for frequent replacements and ensuring reliable performance

Flexibility and Versatility: High temperature resistant hoses are flexible, allowing for easy installation in tight spaces. Their versatility makes them suitable for various applications, from industrial to commercial use

Chemical Resistance: Many chemical resistant high temperature resistant hoses are also resistant to chemicals, making them ideal for transporting corrosive fluids in chemical processing industries

Pressure Handling: These hoses can handle high pressures, making them suitable for applications where both high temperature and high pressure are present

Selection Criteria

Performance Requirements: When selecting, a high temperature resistant hose, consider the maximum temperature and pressure it needs to withstand. Ensure the hose meets the specific requirements of your application to avoid failures and ensure safety

Compatibility: Check the hose’s compatibility with the fluids or gases it will transport. Some materials may react with certain chemicals, so it’s crucial to choose the right hose for your needs. For example, Teflon hoses are ideal for chemical resistance, while silicone hoses are better for flexibility and heat resistance

Cost vs. Benefit: While high temperature resistant hoses may be more expensive than standard hoses, their durability and performance often justify the cost. Consider the long-term benefits and potential cost savings from reduced maintenance and replacements. Investing in a high-quality hose can prevent costly downtime and repairs

Regulatory Compliance: Ensure the hose complies with relevant industry standards and regulations. This is particularly important in industries like food processing and pharmaceuticals, where hygiene and safety are critical

Maintenance and Safety

Inspection and Testing: Regular inspection and testing are essential to ensure the hose’s integrity. Look for signs of wear, cracks, or leaks, and replace the hose if necessary. Implement a routine maintenance schedule to catch potential issues early and prevent failures

Safety Protocols: Follow safety protocols when using high temperature resistant hoses. Ensure proper installation and use protective gear to prevent burns or injuries. Train employees on the correct handling and maintenance procedures to ensure safety

Common Issues and Troubleshooting: Common issues include leaks, blockages, and wear. Regular maintenance and prompt troubleshooting can prevent these problems and extend the hose’s lifespan. If a hose shows signs of damage, replace it immediately to avoid accidents and ensure continuous operation

Future Trends and Innovations for Rubber Hoses

Technological Advances: Advances in materials science are leading to the development of hoses with even higher temperature resistance and improved durability. Innovations like nanotechnology are being explored to enhance hose performance. For example, incorporating nanomaterials can improve the hose’s strength and resistance to extreme conditions

Market Trends: The demand for high temperature resistant hoses is expected to grow, driven by increasing industrialization and the need for efficient and safe fluid transport systems. Market trends indicate a shift towards more sustainable and eco-friendly materials. Manufacturers are focusing on developing hoses that are not only high-performing but also environmentally friendly

Sustainability: There is a growing emphasis on sustainability in the manufacturing of high temperature resistant hoses. This includes using recyclable materials and reducing the environmental impact of production processes. Companies are also exploring ways to extend the lifespan of hoses to reduce waste

Customization: As industries evolve, there is an increasing demand for customized solutions. Manufacturers are offering bespoke hoses tailored to specific applications, ensuring optimal performance and efficiency. This trend is particularly evident in specialized industries like aerospace and pharmaceuticals

High temperature resistant hoses are vital components in many industries, ensuring safe and efficient operation under extreme conditions. By understanding their types, applications, key features, and maintenance requirements, you can make informed decisions and select the right hose for your needs. As technology advances, these hoses will continue to evolve, offering even greater performance and reliability. Investing in high-quality, high temperature resistant hoses can enhance safety, efficiency, and longevity in various applications, making them an essential tool for industries facing extreme conditions.

We can deliver heat resistant hoses in, a few working days after purchase or immediately those which are available from stock. Because of low delivery time we operate in whole Europe and UK. You can find our products online to expose their functionality. Message us or call us for help!

Vent Clip Pur

From: 211,04 € *Unit price per 1 m plus VAT plus shipping costs

Vent Clip Pur

From: 211,04 € *Unit price per 1 m plus VAT plus shipping costs

Vent Clip PE

From: 205,04 € *Unit price per 1 m plus VAT plus shipping costs

Vent Clip PE

From: 205,04 € *Unit price per 1 m plus VAT plus shipping costs

Vent Clip Spark

From: 206,96 € *Unit price per 1 m plus VAT plus shipping costs

Vent Clip Spark

From: 206,96 € *Unit price per 1 m plus VAT plus shipping costs