In the world of industrial applications, the importance of hoses and chemical resistance cannot be overstated. These specialized hoses are designed to handle the harshest chemicals, ensuring safety and efficiency in various processes. We will look into the intricacies of chemical resistant hoses, exploring their materials, applications, benefits in transfer of harsh chemicals and more.

What are Chemical Resistant Hoses?

Group of chemical resistant hoses are specially designed to transport aggressive chemicals without degrading or losing their integrity. They are made from materials such as PTFE (Polytetrafluoroethylene), EPDM (Ethylene Propylene Diene Monomer), and Viton, which are known for their excellent chemical resistance and durability.

- PTFE: Known for its non-reactive properties, PTFE hoses and tubes can handle a wide range of chemicals and temperatures

- EPDM: This synthetic rubber is resistant to heat, ozone, and weathering, making it suitable for outdoor applications

- Viton: A type of fluoroelastomer, Viton hoses are highly resistant to chemicals, oils, and extreme temperatures

Importance and Applications

Chemical resistant hoses are crucial in industries where the safe transfer of hazardous substances is paramount. Key industries include:

- Chemical Processing: Used for transferring acids, solvents, and other corrosive chemicals

- Pharmaceuticals: Essential for maintaining purity and preventing contamination

- Food and Beverage: Ensures safe handling of cleaning agents and other chemicals used in production

Specific applications within these industries range from chemical transfer and loading to cleaning and maintenance processes. For example, in the chemical processing industry, these hoses are used to transport aggressive chemicals from storage tanks to reactors. In the pharmaceutical industry, they are used to transfer high-purity chemicals without contamination. In the food and beverage industry, they ensure that cleaning agents and other chemicals do not contaminate the products.

Key Features and Benefits of a Chemical Hose

Chemical resistant hoses offer several advantages:

- Durability: They are built to withstand harsh chemicals and extreme temperatures, ensuring a long service life

- Safety: By preventing leaks and spills, these hoses enhance workplace safety

- Efficiency: Their robust construction minimizes downtime and maintenance costs, contributing to overall operational efficiency

These hoses are designed to resist the corrosive effects of chemicals, which can cause other types of hoses to degrade quickly. This durability means that chemical resistant hoses need to be replaced less frequently, saving money and reducing downtime. Additionally, the safety benefits of these hoses cannot be overstated. Leaks and spills of hazardous chemicals can cause serious injuries and environmental damage. By preventing these incidents, chemical resistant hoses help to create a safer workplace.

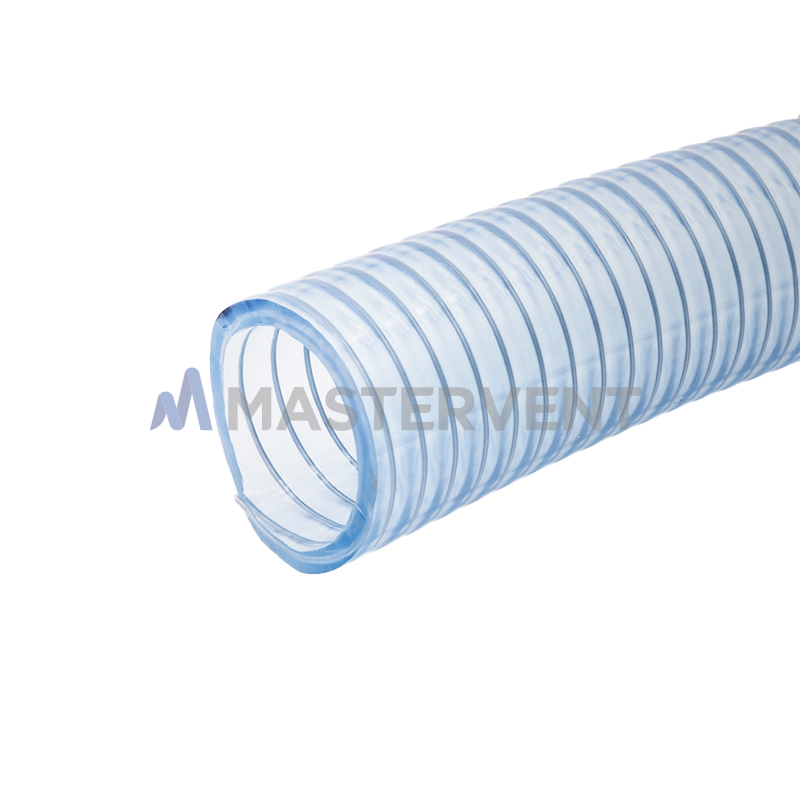

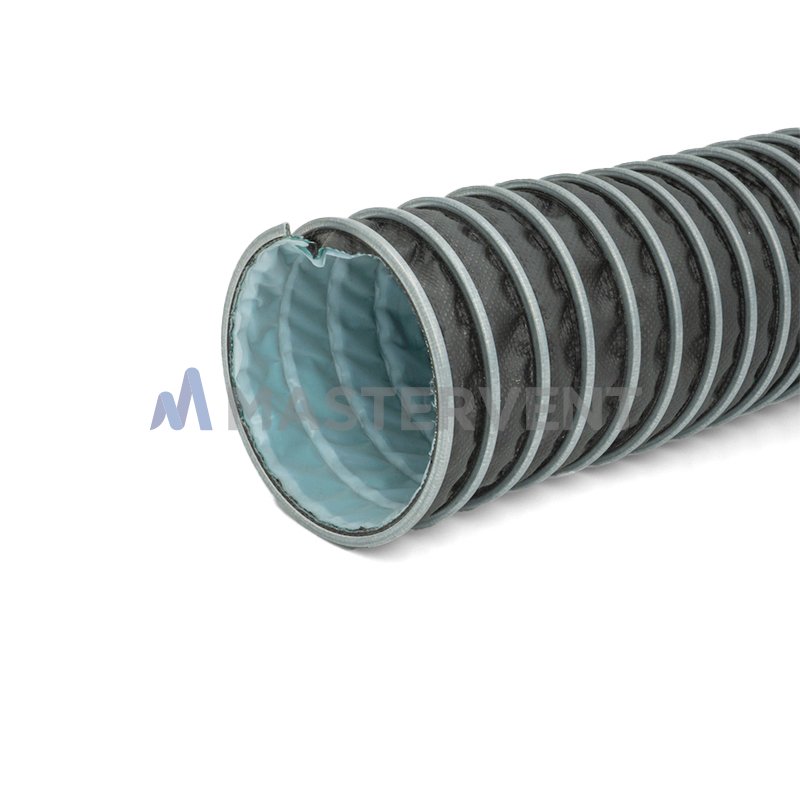

Types of Chemical Resistant Hoses

There are various types of chemical resistant hoses, each suited to different applications:

- Braided Hoses: Known for their flexibility and strength, ideal for high-pressure applications

- Corrugated Hoses: Offer excellent flexibility and are suitable for tight spaces

- Smoothbore Hoses: Provide a smooth interior surface, reducing friction and improving flow rates

Hoses suitable for different media. Each type has its own set of advantages and disadvantages, making it important to choose the right one based on specific needs. Braided hoses, for example, are reinforced with a layer of braided material, which gives them added strength and flexibility. This makes them ideal for high-pressure applications where the hose needs to bend and flex without kinking. Corrugated hoses, on the other hand, have a series of ridges and grooves that give them excellent flexibility. This makes them suitable for applications where the hose needs to be routed through tight spaces. Smoothbore hoses have a smooth interior surface that reduces friction and improves flow rates. This makes them ideal for applications where a high flow rate is required.

Hose assemblies depending on a choice can approve to transport esters and aromatic hydrocarbon, ketones, liquids like animal and vegetable oils moreover either organic or inorganic acids.

Selection Criteria

When selecting, a chemical resistant hose, consider the following factors including inner diameter:

- Chemical Compatibility: Ensure the hose material is compatible with the chemicals being transported

- Temperature Resistance: Choose a hose that can withstand the operating temperatures

- Pressure Rating: Select a hose with an appropriate pressure rating for the application

Additionally, look for hoses that meet relevant standards and certifications to ensure quality and safety. For example, hoses used in the food and beverage industry should meet FDA standards for food contact materials. Hoses used in the pharmaceutical industry should meet USP Class VI standards for biocompatibility. Hoses used in the chemical processing industry should meet ASTM standards for chemical resistance.

Maintenance and Safety Tips

Proper maintenance and handling of chemical resistant hoses are crucial for their longevity and performance:

- Inspection: Regularly inspect hoses for signs of wear, such as cracks or leaks

- Storage: Store hoses in a cool, dry place away from direct sunlight and chemicals

- Handling: Follow manufacturer guidelines for handling and using hoses to prevent damage

Regular inspection of chemical resistant hoses is essential to identify signs of wear and tear before they become serious problems. Look for cracks, leaks, and other signs of damage. If any damage is found, the hose should be replaced immediately. Proper storage is also important to prolong the life of the hose. Store hoses in a cool, dry place away from direct sunlight and chemicals. This will help to prevent the hose from degrading over time. Finally, follow the manufacturer’s guidelines for handling and using the hose. This will help to prevent damage and ensure that the hose performs as expected.

Chemical resistant hoses are indispensable tools in many industries, offering durability, safety, and efficiency. By understanding their features, applications, and maintenance requirements, businesses can make informed decisions and ensure the safe handling of hazardous substances.

Mastervent is a leading hose supplier in Europe. We can supply chemical resistant hoses in a few working days after purchase or immediately those which are available from stock. Our chemical hoses are typically manufactured with steel wire helix, layers of liner electrically conductive or standard textiles fibres, covered by steel reinforcement. Chemical hoses are manufactured for delivery application and suction of paint. You can view our collection of products online, including high value information to expose their functionality. Please message us or call us for help!

Vent Clip Pur

From: 211,04 € *Unit price per 1 m plus VAT plus shipping costs

Vent Clip Pur

From: 211,04 € *Unit price per 1 m plus VAT plus shipping costs

Vent Clip PE

From: 205,04 € *Unit price per 1 m plus VAT plus shipping costs

Vent Clip PE

From: 205,04 € *Unit price per 1 m plus VAT plus shipping costs

Vent Clip Spark

From: 206,96 € *Unit price per 1 m plus VAT plus shipping costs

Vent Clip Spark

From: 206,96 € *Unit price per 1 m plus VAT plus shipping costs